Oil & Gas Industry Solutions

The oil and gas industry is divided into three main segments: upstream, midstream, and downstream. Each segment involves different processes and activities related to the exploration, extraction, transportation, and processing of crude oil/natural gas and mixing is an essential process in all three segments.

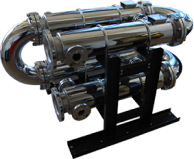

Industrial mixing is integrated throughout the oil and gas industry, playing an important role in ensuring the consistency and uniformity of oil and natural gas products. Mixing is used to blend crude oil and natural gas, remove impurities, regulate temperature, and improve the overall quality of the final product. Our static mixers & direct injection steam heaters for oil & gas can perform this.

At Komax Systems we offer a range of custom, made-to-order products that are specifically designed to provide solutions for the oil and gas industry. These products include static mixers and direct injection steam heaters which can be used to improve the efficiency, performance, and quality of various processes throughout the upstream, midstream, and downstream segments of the oil and gas industry.

Oil and Gas Upstream Applications

The oil and gas upstream industry refers to the initial stage of the oil and gas production process, where oil and natural gas are first discovered and extracted from underground reservoirs. This stage typically involves activities such as drilling, hydraulic fracturing, and well completion.

Industrial heating is used to warm crude oil or natural gas to a temperature that allows it to flow more easily from the underground reservoir to the surface. This is an important step in the refining process as it helps to improve the efficiency and performance of the production process.

Industrial mixing is also used in the upstream industry to homogenize crude oil and natural gas, removing impurities, and improving the overall quality of the final product. Mixing is used to ensure that the fracturing fluid is well blended and its composition is good for this process. The mixing can be achieved by using a variety of mixing technologies, such as inline static mixers, which are designed to mix and blend crude oil and natural gas.

Komax Systems provides a range of products that are specifically designed to provide solutions for the oil and gas upstream industry. These products include Direct Injection Steam Heaters and Custody Transfer static mixers, which can be used to regulate the temperature, homogenize the crude oil and natural gas during the refining process and also ensure efficient extraction of the oil from the reservoirs.

Oil and Gas Mid-Stream Applications

The oil and gas midstream industry refers to the transportation and storage of crude oil and natural gas between the upstream production process and the downstream refining process. This stage of the production process typically involves activities such as pipeline transportation, storage, and terminal operations and often involves the mixing of different types/quality of crude oil to produce a blend that meets specific requirements.

This is an important step since the different types of crude oil can have different properties such as density, viscosity, etc. By mixing them, the processor can create a mixture that meets specific requirements and produce high-quality products that can remain homogeneous during transportation or storage.

Industrial mixing is used in midstream applications to mix the crude oil with any impurities that might be left in the line from extraction (water, sand, trace chemicals, etc.). The crude oil is mixed and sampled when being delivered from one entity to another so that they are confident they are receiving the correct amount of oil that is expected and not an excess of water/contaminants.

Oil and Gas Down-Stream Applications

The oil and gas downstream industry refers to the refining and processing of crude oil and natural gas into finished products, such as gasoline, diesel, and petrochemical products. This stage of the production process typically involves activities such as refining, processing, and distribution.

With the help of Komax’s static mixers, different types of crude oil and/or natural gas can be homogenized, remove impurities, and improve the overall quality of the final product depending on the final refined product requirements.

How Komax’s Products Can Help Your Oil and Gas Project

Within each of the three stages of oil and gas production, Komax Systems’ products are instrumental. Integrating effective and efficient mixing and heating into each step. Mixing is also used in the oil industry for water injection test, chemical dosing and blending of various chemicals, including corrosion inhibitors, demulsifiers, scale inhibitors, and biocides.

Overall, mixing is a critical process in the oil and gas industry and is used to optimize the performance of drilling, oil production, transportation, and refining processes. This ultimately helps with producing high-quality products that meet the specific requirements of the processors.

Related Case Studies

Oil Sands / Mining-Mineral

Oil Sands / Mining-Mineral

Oil Sands / Mining-Mineral

Oil Sands / Mining-Mineral