Static Inline Mixers Industries Served

Our Product FAQs

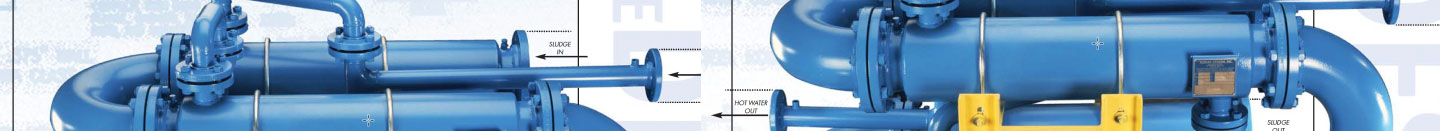

We are an industry leader in advanced inline static mixing and steam heating technologies, creating world-class solutions for clients across a spectrum of industries.

At Komax Systems we offer a number of solutions within the mixing and heating industries. We customize each of our products to each project’s specific needs whether it be an inline static mixer or an industrial heat exchanger. Contact us to get your free quote today!

No, at Komax Systems we do business across the world and ship internationally! Get your quote today!

Komax Systems is based in Huntington Beach, California but does business worldwide. Talk to our salesmen to get your project started today!

If your questions about our products are not answered here, get in touch with us for more information.

See ALl FAQs